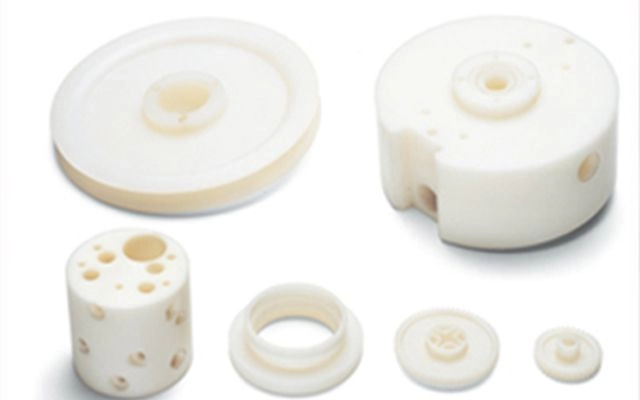

10 Best TPS Extrusion Molded Products in Malaysia

1. TPS - PP | Polypropylene

Extremely Light and Strong

Because PP is the lightest of general-purpose plastics and has superior chemical resistance, it is used in a wide variety of industrial fields.

Uses

- Semiconductor manufacturing equipment components

- Medical devices components

- Food devices components

Characteristics

- PP has excellent electrical properties, as well as superior resistance to water and chemicals.

- PP is the lightest of general-purpose plastics.

Grade List

| Grade | Characteristics |

|---|---|

| PP(NC) | Standard grade |

* Refer to the Products Catalogue on page 44 for product specifications.

Properties Data

| Category | Property | Unit | Test Method ISO | TPS® PP |

|---|---|---|---|---|

| NC | ||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 29 |

| Tensile elasticity | % | >200 | ||

| Bending strength | MPa | 178 | - | |

| Bending elasticity | GPa | - | ||

| Poisson’s ratio | - | - | 0.4 | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | 5.0 | |

| Rockwell hardness | - | - | R85 | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 0.91 |

| Water absorption (23°C, 24 Hrs) | % | - | <0.03 | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | 11 | |

| Flammability (UL) | - | UL94 | - | |

| Thermal properties | Deflection temperature under load (0.45MPa) | °C | 75-1,2 | 80 |

| Continuous use temperature | °C | - | - | |

| Glass transition temperature | °C | - | - | |

| Melting point | °C | - | - | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | - |

| Surface resistance | Ω | IEC60093 | - | |

| Volume resistance | Ω・cm | - | ||

| Permittivity 106Hz | - | IEC60250 | - | |

| Dielectric tangent 106Hz | - | IEC60250 | - | |

| Certified per the Food Sanitation Act | ◯ | |||

- * The values given above for the properties are representative values given by the manufacturers of the raw materials, and are not guaranteed values for the product.

- * The cells with no values given (-) indicate that useful data is not available or cannot be obtained at this time.

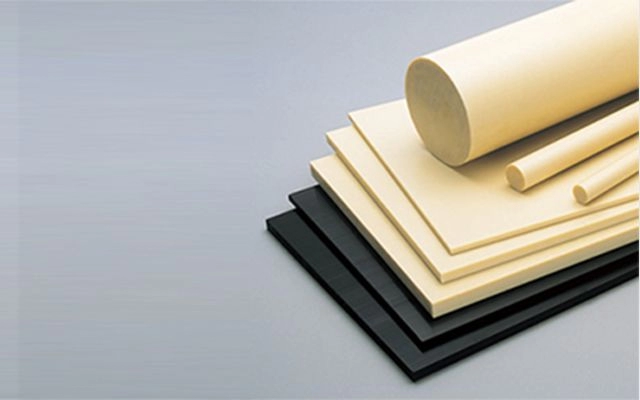

2. TPS - Nylon Series | 6 nylon / 66 nylon

A Typical Industrial Plastic

Nylon (polyamide) is a crystalline plastic with superior mechanical properties, and has superior abrasion/wear resistance, chemical resistance (excluding mineral acids, phenols and the like) and oil resistance, as well as excellent performance as a gas barrier.

Nylon has a high melting point and high water absorption due to its chemical structure. The flexibility and impact resistance of nylon improves when it absorbs water. Nylon 66 has lower water absorption and higher rigidity compared to nylon 6.

Uses

- Automobile and train components

- Electronic and electric device components

- Nylon has low impurities content, and generates extremely little outgases.

- General industrial devices components

Characteristics

- Nylon has superior resistance to bases and solvents.

- Nylon becomes flexible when it absorbs water, and its impact resistance increases.

Grade List

| Grade | Characteristics |

|---|---|

| N6(NC) | Standard grade(unfilled) |

| N6(M) | Wear-resistant grade (molybdenum disulfide added) |

| N6(G30 BK) | Fiberglass reinforced grade |

| N66(NC) | Standard grade(unfilled) |

| N66(G30 BK) | Fiberglass reinforced grade |

* Refer to the Products Catalogue on pages 41 for product specifications.

Properties Data

| Category | Property | Unit | Test Method ISO | TPS® N6 | TPS® N66 | ||

|---|---|---|---|---|---|---|---|

| NC | G30 | NC | G30 | ||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 75 | 185 | 85 | 160 |

| Tensile elasticity | % | 50< | 11 | 50< | 3.0 | ||

| Bending strength | MPa | 178 | 100 | 285 | 110 | - | |

| Bending elasticity | GPa | 2.5 | 9.4 | 2.7 | - | ||

| Poisson’s ratio | - | - | 0.38 | 0.35 | 0.3 | - | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | 5.5 | 15.0 | 4.5 | 70.0 | |

| Rockwell hardness | - | - | - | - | - | R121 | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 1.13 | 1.36 | 1.14 | 1.35 |

| Water absorption (23°C, 24 Hrs) | % | - | 1.8 | - | - | 0.6 | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | - | 2.5 | 8.0 | 2~3 | |

| Flammability (UL) | - | UL94 | HB (0.75mm) |

HB Equivarent | HB (0.71mm) |

HB Equivarent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | 75-1,2 | - | 205 | 70 | 250 |

| Continuous use temperature | °C | - | - | 100 | - | 110 | |

| Glass transition temperature | °C | - | - | 40~60 | 40~60 | 50 | |

| Melting point | °C | - | 225 | 215~225 | 255~265 | 255 | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | - | - | 20.0 | - |

| Surface resistance | Ω | IEC60093 | - | - | - | - | |

| Volume resistance | Ω・cm | - | 1015 | 1015 | - | ||

| Permittivity 106Hz | - | IEC60250 | - | - | - | - | |

| Dielectric tangent 106Hz | - | IEC60250 | - | - | - | - | |

| Certified per the Food Sanitation Act | ◯ | - | ◯ | - | |||

- * The values given above for the properties are representative values given by the manufacturers of the raw materials, and are not guaranteed values for the product.

- * The cells with no values given (-) indicate that useful data is not available or cannot be obtained at this time.

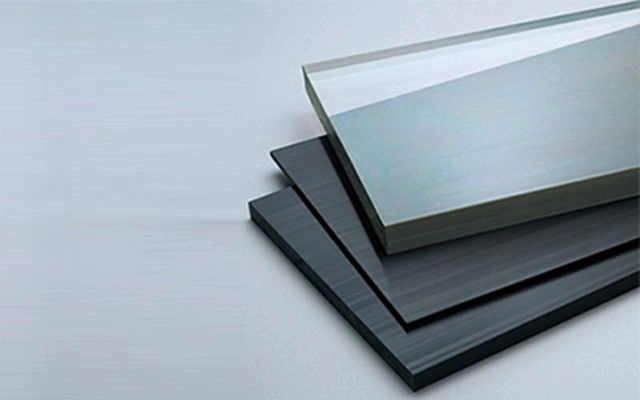

3. TPS - PC | Polycarbonate

Outstanding Impact Resistance

PC is the only engineering plastic that is transparent. It is a non-crystalline plastic with outstanding impact resistance and can be used under a broad range of temperatures. PC also has superior creep resistance, and because of its low water absorption, has excellent dimension stability. Its electrical properties are also extremely good, but because of its low resistance to chemicals and propensity for stress cracks, care must be exercised.

Uses

- Optics-related components

- Electric/electronic devices components

- Medical devices components

- Food devices components

Characteristics

- PC (NC)-I has superior transparency.

- PC has superior impact resistance, as well as excellent heat and cold resistance.

- PC (BK) is a light-proof grade.

Grade List

| Grade | Characteristics |

|---|---|

| PC (NC)-I | Standard grade(transparent, ice-color) |

| PC (BK) | Standard grade(black, light-proof) |

| PC (G20BK) | Glass-reinforced grade |

* Refer to the Products Catalogue on page 43 for product specifications.

Properties Data

| Category | Property | Unit | Test Method ISO | TPS® PC | |

|---|---|---|---|---|---|

| NC-I | BK | ||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 75 | 65 |

| Tensile elasticity | % | 50< | 50< | ||

| Bending strength | MPa | 178 | 91 | 100 | |

| Bending elasticity | GPa | 2.3 | 2.3 | ||

| Poisson’s ratio | - | - | - | - | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | ≧65.0 | ≧5.0 | |

| Rockwell hardness | - | - | - | - | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 1.20 | 1.20 |

| Water absorption (23°C, 24 Hrs) | % | - | 0.20 | 0.20 | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | 6.5 | 6.5 | |

| Flammability (UL) | - | UL94 | V-2 (0.40mm) |

V-2 (0.40mm) |

|

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | 75-1,2 | 130 | 130 |

| Continuous use temperature | °C | - | 115 | 115 | |

| Glass transition temperature | °C | - | 130~150 | 130~150 | |

| Melting point | °C | - | - | - | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | 30.0 | 30.0 |

| Surface resistance | Ω | IEC60093 | 1015 | 1015 | |

| Volume resistance | Ω・cm | 1013 | 1013 | ||

| Permittivity 106Hz | - | IEC60250 | 3.10 | 3.10 | |

| Dielectric tangent 106Hz | - | IEC60250 | 0.0090 | 0.0090 | |

| Certified per the Food Sanitation Act | ○ | ○ | |||

- * The values given above for the properties are representative values given by the manufacturers of the raw materials, and are not guaranteed values for the product.

- * The cells with no values given (-) indicate that useful data is not available or cannot be obtained at this time.

4. TPS - PBT | Polybutyleneterephthalate

High Toughness, High Rigidity and Superior Resistance to Heat Aging

PBT is the newest crystalline plastic among engineering plastics, and has high toughness and rigidity, as well as superior resistance to heat aging (it maintains good mechanical properties even under high temperatures).

PBT also has good electrical properties under a broad range of temperatures. It has low water absorption, excellent climate and chemical resistance, and is well-balanced.

Uses

- Electric/electronic devices components

- Automobile components

Characteristics

- PBT can be used continuously at 130°C.

- PBT has good electrical properties.

- PBT has stable dimension changes due to low water absorption.

Grade List

| Grade | Characteristics |

|---|---|

| PBT(NC) | Standard grade |

| PBT(G30NC) | Fiberglass reinforced grade |

* Refer to the Products Catalogue on page 42 for product specifications.

Properties Data

| Category | Property | Unit | Test Method ISO | TPS® PBT | |

|---|---|---|---|---|---|

| NC | G30 NC |

||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 53 | 135 |

| Tensile elasticity | % | 108.0 | 3.0 | ||

| Bending strength | MPa | 178 | - | - | |

| Bending elasticity | GPa | 2.44 | - | ||

| Poisson’s ratio | - | - | 0.35 | - | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | 3.9 | - | |

| Rockwell hardness | - | - | - | - | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 1.31 | 1.53 |

| Water absorption (23°C, 24 Hrs) | % | - | - | 0.15 | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | - | 2~3 | |

| Flammability (UL) | - | UL94 | HB Equivarent | HB Equivarent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | 75-1,2 | 59 | 210 |

| Continuous use temperature | °C | - | - | 110 | |

| Glass transition temperature | °C | - | 35 | 60 | |

| Melting point | °C | - | 223 | 225 | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | - | 50.0 |

| Surface resistance | Ω | IEC60093 | - | 1015 | |

| Volume resistance | Ω・cm | - | - | ||

| Permittivity 106Hz | - | IEC60250 | - | 3.8 | |

| Dielectric tangent 106Hz | - | IEC60250 | - | 0.009 | |

| Certified per the Food Sanitation Act | - | - | |||

- * The values given above for the properties are representative values given by the manufacturers of the raw materials, and are not guaranteed values for the product.

- * The cells with no values given (-) indicate that useful data is not available or cannot be obtained at this time.

5. TPS - PPS | Polyphenylene Sulfide

Chemical Resistance, High Strength and Dimensional Stability

PPS is a crystalline plastic with high heat resistance (continuous use temperature of approximately 220°C) and superior mechanical strength, rigidity, flame resistance, chemical resistance, electrical properties and dimensional stability. The market for PPS has recently been expanding rapidly, taking advantage of its superior characteristics.

Uses

The primary uses of PPS is as electric/electronic components, automobile components, mechanical components (e.g., chemical pump), and components for semiconductor/liquid crystal manufacturing and testing equipment.

Characteristics

- PPS has superior dimension stability because of its extremely low water absorption and low linear expansion coefficient.

- PPS is extremely resistant to chemicals, and can withstand not only organic acids such as acetic acid but also strong inorganic acids such as hydrochloric and sulfuric acid. It is also not affected by strong bases.

- Although it has a high continuous use temperature of 220°C, it has a low glass transition temperature of 90°C; therefore care is required when PPS is used under high temperatures and high loads.

- PPS has high strength and high rigidity, as well as superior resistance to fatigue and creep.

- The grade recommended for superior sliding wear is PPS230AE3.

Comparison of General Physical Properties

Grade List

| Grade | Characteristics |

|---|---|

| PPS (NC) SC | Standard grade(unfilled) |

| PPS (G40BK) | Fiberglass reinforced grade(black) |

| PPS 230-AE3 | AE grade (conductive) |

| PPS 2001 | High-function sheets (unfilled grade with a thickness of 0.2 to 2 mm) |

* Refer to the Products Catalogue on page 36 for product specifications.

Properties Data

| Category | Property | Unit | Testing Method ASTM | TPS® PPS | ||

|---|---|---|---|---|---|---|

| NC-SC | G40 | 230-AE3 | ||||

| BK | ||||||

| Mechanical properties | Tensile strength | MPa | D638 | 79 | 167 | 98 |

| Tensile elasticity | % | 23.0 | 2.0 | 5.0 | ||

| Bending strength | MPa | D790 | 128 | 235 | 150 | |

| Bending elasticity | GPa | 3.3 | 11.8 | 6.2 | ||

| Poisson’s ratio | - | - | 0.37 | 0.4 | - | |

| Compressive strength | MPa | D695 | - | - | - | |

| Izod impact strength (notched) | J/m | D256 | 15 | 157 | 45 | |

| Rockwell hardness | - | D785 | - | M80 | M98 | |

| Physical properties | Specific gravity (23°C) | - | D792 | 1.35 | 1.59 | 1.40 |

| Water absorption (23°C, 24 Hrs) | % | D570 | 0.02 | 0.02 | 0.02 | |

| Linear expansion coefficient | ×10-5 /°C |

JIS K7197 | 2.4~2.9 | 1.7~6.8 | - | |

| Thermal conduction | W/mK | E 1530 | 0.20 | - | - | |

| Flammability (UL) | - | D570 | V-0 equivalent | V-2 (0.8mm) |

V-0 equivalent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | D648 | 112 | 260 | 173 |

| Continuous use temperature | °C | - | 220 | 220 | 220 | |

| Glass transition temperature | °C | - | 88 | - | 88 | |

| Melting point | °C | - | 278 | - | 278 | |

| Electrical properties | Dielectric strength | MV/m | D149 | 15.0 | 18.0 | - |

| Surface resistance | Ω | D257 | 1016 | 1016 | 101~6 | |

| Volume resistance | Ω・cm | 1018 | 1016 | - | ||

| Permittivity 106Hz | - | D150 | 3.6 | 4.1 | - | |

| Dielectric tangent 106Hz | - | 0.0011 | 0.003 | - | ||

| Certified per the Food Sanitation Act | ◯ | - | - | |||

- * The values given above for the properties are representative values given by the manufacturers of the raw materials, and are not guaranteed values for the product.

- * The cells with no values given (-) indicate that useful data is not available or cannot be obtained at this time.

- * AE stands for anti-electrostatic, and is an abbreviation for our anti-electrostatic grade material.

_Material_.png)

6. TPS-Anti-Electrostatic (AE) Material

Anti-Electrostatic and Heat Resistant

AE (anti-electrostatic) materials are a high-function material developed to meet the growing need for preventing electrostatic charge and dust adhesion. The TI-5000 series, PEEK, PPS, POM and ABS are used as the base plastic for AE material, which are classified into three types depending on the surface resistance zone.

Types List:

Grade List:

- The surface resistance figures are based on the measurements for the resin starter materials according to the ASTM-D257 measuring method, but verify the antistatic effect using an operational suitability test when actually using the material.

- Refer to the Products Catalogue on pages 45 for product specifications.

Properties Data:

| Category | Property | Unit | Testing Method ASTM | TI530-AE3 | PEEK 430-AE3 |

PPS 230-AE3 |

|---|---|---|---|---|---|---|

| Mechanical properties | Tensile strength | MPa | D638 | 100 | 98 | 98 |

| Tensile elasticity | % | 3.5 | 4.0 | 5.4 | ||

| Bending strength | MPa | D790 | 137 | 160 | 150 | |

| Bending elasticity | GPa | 10.8 | 4.2 | 6.2 | ||

| Poisson’s ratio | - | - | - | - | - | |

| Compressive strength | MPa | D695 | - | - | - | |

| Izod impact strength (notched) | J/m | D256 | 37 | 39 | 45 | |

| Rockwell hardness | - | D785 | M95 | M100 | M98 | |

| Physical properties | Specific gravity (23°C) | - | D792 | 1.55 | 1.33 | 1.40 |

| Water absorption (23°C, 24 Hrs) | % | D570 | - | - | 0.02 | |

| Linear expansion coefficient | ×10-5 /°C |

JIS K7197 | 1.3 | 3.5 | - | |

| Thermal conduction | W/mK | E 1530 | - | - | - | |

| Flammability (UL) | - | D570 | V-0 (0.75mm) |

V-0 equivalent | V-0 equivalent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | D648 | 280 | 164 | 173 |

| Continuous use temperature | °C | - | 250 | 260 | 220 | |

| Glass transition temperature | °C | - | 280 | 143 | 88 | |

| Melting point | °C | - | - | 343 | 278 | |

| Electrical properties | Dielectric strength | MV/m | D149 | - | - | - |

| Surface resistance | Ω | D257 | 101~6 | 101~6 | 101~6 | |

| Volume resistance | Ω・cm | 101~6 | 101~6 | - | ||

| Permittivity 106Hz | - | D150 | - | - | - | |

| Dielectric tangent 106Hz | - | - | - | - | ||

| Certified per the Food Sanitation Act | - | - | - | |||

- The values given above for the properties are representative values given by the manufacturers of the raw materials, and are not guaranteed values for the product.

- The cells with no values given (-) indicate that useful data is not available or cannot be obtained at this time.

- AE stands for anti-electrostatic, and is an abbreviation for our anti-electrostatic grade material.

7. TPS-PEEK | Polyetheretherketone

Heat Resistance, Flame Resistance and Chemical Resistance

PEEK is a crystalline plastic with properties that have not been conventionally available; it has high heat resistance (continuous use temperature of 260°C), as well as superior chemical resistance and hot water resistance. It is also a plastic with high flame resistance and extremely low generation of smoke and corrosive gases upon combustion.

Uses:

The primary uses for PEEK are as semiconductor/liquid crystal manufacturing equipment components, testing equipment components, medical equipment components and the like.

Characteristics:

- PEEK has superior resistance to hot water, and can be used continuously in steam at 200 to 260°C. It can withstand a temperature of 300°C for short periods of time, and among plastics, it has the highest resistance to hot water.

- PEEK has superior chemical resistance, and extremely superior resistance to acids and bases under high temperatures. It is, however, affected by concentrated sulfuric acid.

- PEEK has a high continuous use temperature of 260◦C, but because its glass transition temperature is low at 143◦C, it requires care when being used under high temperatures and high loads.

- PEEK is a plastic with high flame resistance, with minimal generation of smoke and toxic gases upon combustion.

- The recommended grades for high sliding wear resistance are PEEK (NC), PEEK 430-AE3, PEEK 4000 and PEEK 4110.

Comparison of General Physical Properties:

Grade List:

| Grade | Characteristics |

|---|---|

| PEEK(NC) | Standard grade |

| PEEK430-AE3 | AE grade (conductive) |

| PEEK 4000 | High-function sheets (unfilled grade with a thickness of 0.1 to 0.5 mm) |

| PEEK 4110 | High-function sheets (high-sliding grade with a thickness of 0.1 to 0.5 mm) |

* Refer to the Products Catalogue on page 35 for product specifications.

Properties Data:

| Category | Property | Unit | Testing Method ASTM | TPS® PEEK | |

|---|---|---|---|---|---|

| NC | 430-AE3 | ||||

| Mechanical properties | Tensile strength | MPa | D638 | 98 | 98 |

| Tensile elasticity | % | >60 | 4.0 | ||

| Bending strength | MPa | D790 | 170 | 160 | |

| Bending elasticity | GPa | 4.2 | 4.2 | ||

| Poisson’s ratio | - | - | 0.4 | - | |

| Compressive strength | MPa | D695 | 118 | - | |

| Izod impact strength (notched) | J/m | D256 | 67 | 39 | |

| Rockwell hardness | - | D785 | M99 | M100 | |

| Physical properties | Specific gravity (23°C) | - | D792 | 1.32 | 1.33 |

| Water absorption (23°C, 24 Hrs) | % | D570 | 0.5 | - | |

| Linear expansion coefficient | ×10-5 /°C |

JIS K7197 | 4.7~10.8 | 3.5 | |

| Thermal conduction | W/mK | E 1530 | 0.26 | - | |

| Flammability (UL) | - | D570 | V-0 (1.5mm) |

V-0 equivalent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | D648 | 152 | 164 |

| Continuous use temperature | °C | - | 260 | 260 | |

| Glass transition temperature | °C | - | 143 | 143 | |

| Melting point | °C | - | 343 | 343 | |

| Electrical properties | Dielectric strength | MV/m | D149 | - | - |

| Surface resistance | Ω | D257 | 1016 | 101~6 | |

| Volume resistance | Ω・cm | 1016 | 101~6 | ||

| Permittivity 106Hz | - | D150 | - | - | |

| Dielectric tangent 106Hz | - | - | - | ||

| Certified per the Food Sanitation Act | ◯ | - | |||

- * The values given above for the properties are representative values given by the manufacturers of the raw materials, and are not guaranteed values for the product.

- * The cells with no values given (-) indicate that useful data is not available or cannot be obtained at this time.

- * AE stands for anti-electrostatic, and is an abbreviation for our anti-electrostatic grade material.

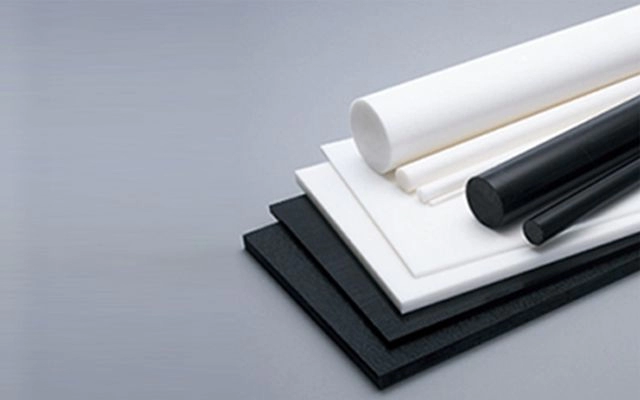

8. TPS-POM | Polyacetal

Balanced Mechanical Characteristics:

POM is a crystalline plastic with balanced mechanical characteristics. It is an engineering plastic that has extremely superior fatigue resistance and good creep resistance. It also has superior wear resistance, chemical resistance, creep resistance and dimension stability. However, because it contains much oxygen in its molecule, it is difficult to make it non-combustible, and its weathering resistance is not very high.

Uses:

- Semiconductor manufacturing equipment components

- Electronic devices components

- Food devices components

- General industrial devices components

Characteristics:

- POM is an excellent material with superior physical properties, low cost and good cutting processability.

- With respect to chemical resistance, POM is resistant to organic solvents and bases, but is affected by strong acids.

- POM is available in a wide variety of forms, ranging from rods (including hollow and super-rods) in diameters of 3 mm to 250 mm to sheets with thicknesses of 0.2 mm to 100 mm and plates.

Grade List:

| Grade | Characteristics |

|---|---|

| POM (NC), (BK) | Standard grade (Natural color, Black) |

| POM (NC), (BK)Super | Low-warp grade (Natural color, Black) |

| POM (G25NC) | Fiberglass reinforced grade |

| POM 131-AE3 | AE grade (conductive) |

* Refer to the Products Catalogue on pages 37 through 40 for product specifications.

Properties Data:

| Category | Property | Unit | Test Method ISO | TPS® POM | ||

|---|---|---|---|---|---|---|

| NC・BK | G25 | 131-AE3 | ||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 57 | 136 | 59 |

| Tensile elasticity | % | 40.0 | 3.0 | 16.0 | ||

| Bending strength | MPa | 178 | 76 | 200 | 87 | |

| Bending elasticity | GPa | 2.2 | 7.9 | 2.4 | ||

| Poisson’s ratio | - | - | 0.35 | 0.38 | - | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | 8.5 | 8.0 | 5.4 | |

| Rockwell hardness | - | - | M78 | M79 | - | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 1.41 | 1.59 | 1.42 |

| Water absorption (23°C, 24 Hrs) | % | - | 0.22 | 0.29 | - | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | 10 | 3~9 | - | |

| Flammability (UL) | - | UL94 | HB (0.75mm) |

HB (0.81mm) |

HB Equivarent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | 75-1,2 | 110 | 162 | - |

| Continuous use temperature | °C | - | 100 | 105 | - | |

| Glass transition temperature | °C | - | -60 | - | - | |

| Melting point | °C | - | 163 | 165 | - | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | 19.0 | 24.0 | - |

| Surface resistance | Ω | IEC60093 | 1016 | 1016 | 101~6 | |

| Volume resistance | Ω・cm | - | 1014 | 101~6 | ||

| Permittivity 106Hz | - | IEC60250 | - | - | - | |

| Dielectric tangent 106Hz | - | IEC60250 | - | - | - | |

| Certified per the Food Sanitation Act | ◯ | - | - | |||

- The values given above for the properties are representative values given by the manufacturers of the raw materials, and are not guaranteed values for the product.

- The cells with no values given (-) indicate that useful data is not available or cannot be obtained at this time.

- AE stands for anti-electrostatic, and is an abbreviation for our anti-electrostatic grade material.

9. TPS-ABS | Acrylonitrile Butadiene Styrene Copolymer

Pleasing to the Eye and Withstanding Impact.

ABS is a thermoplastic resin produced by copolymerizing acrylonitrile, butadiene and styrene.

Uses:

- Optics-related components

- Electric/electronic devices components

- Medical devices components

- Food devices components

Characteristics:

- With respect to chemical resistance, ABS dissolves in solvents but withstands bases and acids.

- ABS has excellent adhesiveness and coating application property, and is widely used as a cutting material for models.

- ABS has high surface hardness and good luster.

ABS Super (Low-Warping Blade)

Plastic materials used in prototype models are processed in an extremely complex and precise manner. It is very difficult to finish conventional materials in a highly precise manner; therefore, the need for low-warping materials is growing rapidly. In response to such need, we have developed an ABS plastic of a low-warping grade using the know-how developed for our popular TPS® POM Super.

Characteristics:

- The amount of deformation of the ABS Super is approximately one-half that of conventional products.

- Processing time can be shortened due to minimal changes in dimensions and shape during cutting.

Properties:

Grade List:

| Grade | Characteristics |

|---|---|

| ABS (NC), (BK), (WH) | Standard grade (natural color, black, white) |

| ABS (NC), (BK) Super | Low-warping grade (natural color, black) |

* Refer to the Products Catalogue on pages 43 to 44 for product specifications.

Properties Data:

| Category | Property | Unit | Testing Method ASTM | TPS® ABS |

|---|---|---|---|---|

| NC ・ BK | ||||

| Mechanical properties | Tensile strength | MPa | D638 | 45 |

| Tensile elasticity | % | 50< | ||

| Bending strength | MPa | D790 | 65 | |

| Bending elasticity | GPa | 2.1 | ||

| Poisson’s ratio | - | - | - | |

| Izod impact strength (notched) | J/m | D256 | 275 | |

| Rockwell hardness | - | - | R100 | |

| Physical properties | Specific gravity (23°C) | - | D792 | 1.04 |

| Water absorption (23°C, 24 Hrs) | % | - | 0.3 | |

| Linear expansion coefficient | ×10-5/°C | D696 | 8.3 | |

| Flammability (UL) | - | UL94 | - | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | D648 | 86 |

| Continuous use temperature | °C | - | 55 | |

| Glass transition temperature | °C | - | - | |

| Melting point | °C | - | - | |

| Electrical properties | Dielectric strength | MV/m | D149 | - |

| Surface resistance | Ω | D257 | - | |

| Volume resistance | Ω・cm | - | ||

| Permittivity 106Hz | - | D150 | - | |

| Dielectric tangent 106Hz | - | D150 | - | |

| Certified per the Food Sanitation Act | - | |||

- The values given above for the properties are representative values given by the manufacturers of the raw materials, and are not guaranteed values for the product.

- The cells with no values given (-) indicate that useful data is not available or cannot be obtained at this time.

10.TPS-TI 5000 Series | PAI: Polyamide-imide

We specialize in delivering high-quality plastic solutions tailored to meet diverse industrial needs. With an extensive range of innovative materials and a commitment to excellence, we serve as a reliable partner for businesses seeking top-notch engineering plastics.

At our core, we prioritize customer satisfaction by offering personalized solutions and dedicated support throughout every stage of the procurement process. Our goal is to be the go-to source for superior materials and unmatched service, ensuring our clients achieve their objectives with confidence and efficiency. Please contact us if you wish to know more about TPS-TI 5000 Series | PAI: Polyamide-imide.

Aug 07,2024